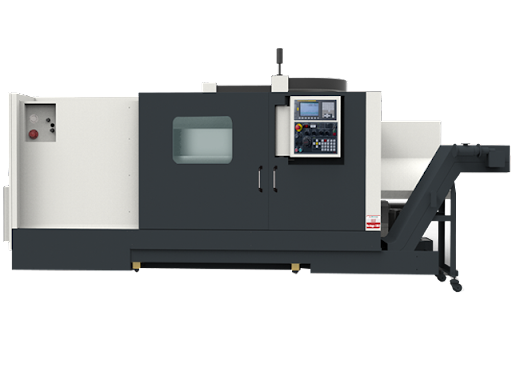

| LL20T L5 CNC LATHE | Unit | Data |

|---|---|---|

| Capacity | ||

| Swing over bed,dia | mm | 510 |

| Swing over carriage,dia | mm | 340 |

| Admit between centres | mm | 610 |

| Max. turning length (with chuck) | mm | 500* |

| Interference free facing diameter | mm | 265 |

| Maximum turning diameter | mm | 320 |

| Chuck Size | mm | 200 |

| Spindle | ||

| (Standard) Spindle nose | Type | A2-8 |

| Hole through spindle | mm | 61 |

| Max. bar capacity | mm | 51 |

| Spindle motor power | KW 7.5/11 | |

| Spindle speed | RPM | 3500 |

| 3Turret | ||

| Actuation type Hydraulic,8 station | - | - |

| Maximum u drill diameter | mm | 40 |

| Maximum boring bar diameter | mm | 40 |

| LR30T L7 CNC LATHE | Unit | Data |

|---|---|---|

| Capacity | ||

| Swing over bed,dia | mm | 680 |

| Swing over carriage,dia | mm | 470 |

| Admit between centres | mm | 820 |

| Max. turning length (with chuck) | mm | 700* |

| Interference free facing diameter | mm | 330 |

| Maximum turning diameter | mm | 470 |

| Chuck Size | mm | 305 |

| Spindle | ||

| (Standard) Spindle nose | Type | A2-8 |

| Hole through spindle | mm | 77 |

| Max. bar capacity | mm | 65 |

| Spindle motor power | KW 15 / 18.5 | |

| Spindle speed | RPM | 2500 |

| 3Turret | ||

| Actuation type Hydraulic,8 station | - | - |

| Maximum u drill diameter | mm | 50 |

| Maximum boring bar diameter | mm | 50 |

| X axis | 1016 mm |

| Y axis | 508 mm |

| Z axis | 635 mm |

| Table Size X | 1219 mm |

| Table Size Y | 457 mm |

| Spindle | BT- 40 ,8100 RPM |

| Spindle driver | 22.3kw |

| Spindle Max Torque | 122 NM @ 2000 rpm |

| ATC | 24 Tool Changer station |

| Controller | Fanuc / Siemens |

| Feed | 25.4 m / Min |

| Instrument Name | Make | Range / Size | Qty | Unit | Least Count / Graduation |

|---|---|---|---|---|---|

| MICROMETER | Mitutoyo | 0 TO 100 | 1 | mm | 0.01 mm |

| MICROMETER | Mitutoyo | 100 TO 200 | 1 | mm | 0.01 mm |

| BORE GAUGE | Mitutoyo | 18 TO 35 | 1 | mm | NA |

| BORE GAUGE | Mitutoyo | 35 TO 60 | 1 | mm | NA |

| BORE GAUGE | Mitutoyo | 50 TO 150 | 1 | mm | NA |

| DIAL GAUGE | Mitutoyo | 0 TO 10 | 1 | mm | 0.01 mm |

| DIAL VERNIER CALIPER | Mitutoyo | 0 TO 150 | 2 | mm | 0.02 mm |

| DIAL VERNIER CALIPER | Mitutoyo | 0 TO 200 | 2 | mm | 0.02 mm |

| DIAL VERNIER CALIPER | Mitutoyo | 0 TO 300 | 2 | mm | 0.02 mm |

| VERNIER CALIPER | Mitutoyo | 0 TO 1000 | 2 | mm | 0.02 mm / 0.05 mm |

| DEPTH/HOOK VERNIER | Mitutoyo | 0 TO 300 | 2 | mm | 0.02 mm |

| Analog HEIGHT GAUGE | Mitutoyo | 0 TO 600 | 1 | mm | 0.01 mm / 0.02 mm |

| PLUNGER DIAL INDICATOR | Mitutoyo | 0 TO 0.8 | 1 | mm | 0.01 mm |

| COMBINATION SET | Mitutoyo/ KRISTAL | 0° TO 90° | 1 | Deg. | NA |

| RADIUS GAUGE | Mitutoyo/ KRISTAL | - | 1 | mm/Inch | NA |

| THREAD PITCH GAUGE | KRISTEEL | - | 1 | mm/Inch | NA |

| FEELER GAUGE | KRISTEEL | - | 1 | mm/Inch | NA |

| V-BLOCK SET | Insize | - | 2 | - | NA |

| INSIDE DIAL CALIPER GAUGE | TECLOCK | 20 TO 35 | 1 | mm | 0.01mm |

| INSIDE DIAL CALIPER GAUGE | TECLOCK | 30 TO 62 | 1 | mm | 0.01mm |

| INSIDE DIAL CALIPER GAUGE | TECLOCK | 55 TO 153 | 1 | mm | 0.01mm |

| SURFACE PLAT | MICRO FLAT DATAMS | 1000 x 630 | 1 | mm | 0 grade |

| BORE GAUGE | Insize | 250 - 450 mm | 1 | mm | - |

| DIGITAL VERNIER CALIPER | Insize | 0-300 mm | 1 | mm | 0.01mm |

| Swing Over bed | 680 mm |

| Chuck dia. Max | 304 mm |

| Max. Turning dia | 470 mm |

| Max. Turning Length | 400 mm |

| Hole through spindle | 77 mm |

| Travel X - Axis | 260 mm |

| Travel Z - Axis | 500 mm |

| No. of stations | 8 nos. |

| Max. Boring bar dia | 50 mm |

| Tool shank size | 25 x 25 mm |

| Max. Boring bar dia | 50 mm |

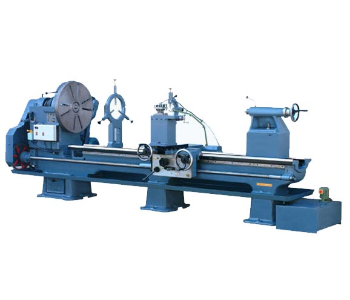

| Maximum Turning Diameter | 580 mm |

| Maximum Turning Length | 1000 mm |

| Spindle Size | A2-6(A2-8) |

| Swing Over Bed | 640 mm |

| Swing Over Carriage | 400 mm |

| Distance Between Centers | 1180 mm |

| Bore Through Spindle | 63 mm |

| X-Axis | 300 mm |

| Z-Axis Stroke | 1000 mm |

| Tailstock Base Travel | 1000 mm |

No. of Machine : 5 NOS

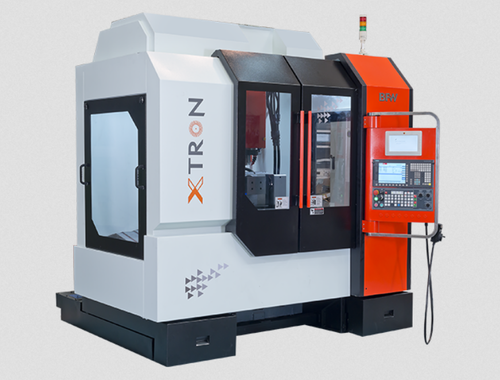

| Table longitudinal travel (X - Axis) | 580 mm |

| Table cross travel (Y - Axis) | 400 mm |

| Headstock travel (Z - Axis) | 400 mm |

| Spindle nose face to table top | 150 - 550 mm |

| Increased daylight area with column height block(Optional) | 350 - 750 mm |

| Distance from Floor to table | 975 mm |

| BSpindle center - column front distance | 480 mm |

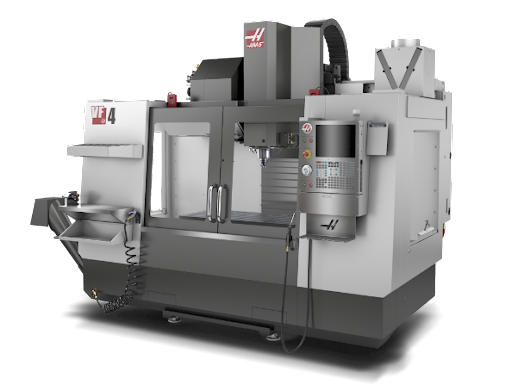

| X axis | 1016 mm |

| Y axis | 508 mm |

| Z axis | 635 mm |

| Table Size X | 1219 mm |

| Table Size Y | 457 mm |

| Spindle | BT- 40 ,8100 RPM |

| Spindle driver | 22.3kw |

| Spindle Max Torque | 122 NM @ 2000 rpm |

| ATC | 24 Tool Changer station |

| Controller | Fanuc / Siemens |

| Feed | 25.4 m / Min |

No. of Machine : 3 NOS

| wing Over bed | 480 mm |

| Chuck Size | 200d mm |

| Max. Turning dia | 130 mm |

| Max. Turning Length | 230 mm |

| Travel X - Axis | 250 mm |

| Travel Z - Axis | 300 mm |

No. of Machine : 3 NOS

| Brand | Ace Microsmatic |

| Maximum Turning Diameter | 320 mm |

| Maximum Turning Length | 300 mm |

| Spindle Size | A2-5 |

| Distance Between Canters | 312 mm |

| Max Bar Capacity | 25(36) mm |

| Standard Chuck | 165 mm |

| X-Axis Stroke | 165 mm |

| No Of Machine | 2 Nos. |

| Z-Axis Stroke | 300 mm |

No. of Machine : 2 NOS

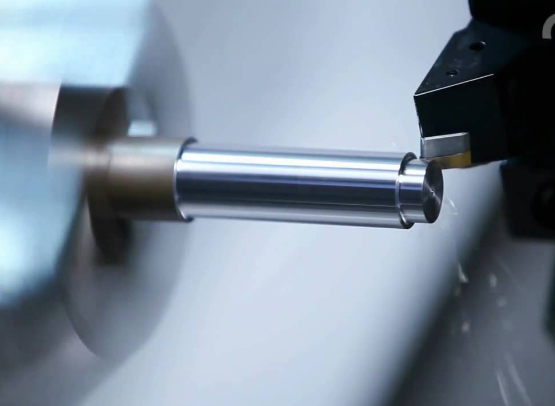

Traub machine is simply based on cam system. A motor helps three shaft to spin as per required speed .These shaft have cam mounted on them which help to move the slide holding cutting tool. its fully systematic mechanism. And another motor helps to turn the main spindle which holds the raw material. Different cam size for different components is used depending on requirements.

Zenfin Supply components to Automobile, Switchgear & Engineering Industries. As per customers requirement. We introduce ourselves as a manufacturer & exporter engaged in the supply of various types of quality fasteners. Our manufacturing unit is equipped with latest manufacturing & testing facilities and has very strict quality control at every stage from procurement of raw materials to dispatch of goods. Some basic components manufactured on Traub are Washers, Nut, Bush , Pin , Dowel Etc.

Vibratory finishing is a type of mass finishing manufacturing process used to deburr, radius, descale, burnish, clean, and brighten a large number of relatively small work pieces

In this batch-type operation, specially shaped pellets of media and the work pieces are placed into the tub of a vibratory tumbler. The tub of the vibratory tumbler and all of its contents are then vibrated. The vibratory action causes the media to rub against the work pieces which yield the desired result. Depending on the application this can be either a dry or wet process

Ultrasonic cleaning is suitable for cleaning a wide variety of materials, including metals, glass, rubber, ceramics and some hard plastics. Ultrasonic cleaning is especially useful for removing tightly-adhered contaminants from intricate items with blind holes, cracks and recesses. Examples of contaminants removed through ultrasonic cleaning include dust, dirt, oil, grease, pigments, flux agents, fingerprints and polishing compound.

We are having LMG-300 A Double Column Fully Automatic Band Saw Machine. These high quality bandsaw machine are made by using very high quality raw material which ensures hassle free work performance at high accuracy.